Leather furniture is a popular choice for many homeowners. Its luxurious and timeless look can add a touch of sophistication to any room. But leather furniture is more than just a pretty face - it's also durable and easy to care for. In this guide, we will discuss the history of leather furniture, the different types of leather, and the process used to create leather furniture. So, whether you're considering purchasing your first piece of leather furniture or you just want to learn more about this popular type of furniture, this guide is for you!

History of Leather

The history of leather is actually incredibly interesting. After all, before using it for furniture, we needed it simply to survive. Hides and leather have been used to clothe, shelter, protect and transport mankind long before we used them for our couches.

The earliest instance of the usage of animal hides has been tied to the Australopithecus, the inhabitants of Africa, 2 million years ago. This group used stone tools to make use of animal hides for protection and shelter from the elements. There were even cave paintings from the Upper Paleolithic period that showed men and women produced from animal hides.

The Neolithic Period was when animal skins started to be used more for clothing, rather than simple protection. The Areni-1, was a shoe found in Armenia, that dates back to 3,500 B.C. and is made of cowhide and is the oldest known leather footwear. From this point onwards, different cultures around the world steadily started to become developed further.

Image source: araratour.com

In the Middle Ages, there was evidence that leather was first stretched over chairs, making this possibly the first use of leather in furniture. The primary process for tanning at this time was Vegetable Tanning, a method of using tree and plant extracts to convert perishable hides to leather.

It's interesting how leather used to be crucial for our survival against the elements, which demonstrates its durability and dependability. Now, it is a luxury for our furniture, cars, and clothes. Something that demonstrates sophistication, and shows signs of growth.

What Is Leather Made From?

Leather is, as you might have guessed, produced from the skin or hide of an animal. However, there are layers to the source and structure of the leather. Hides are from the skin of a large, full-grown animal such as a bovine, or cattle. Skin is a term used to describe smaller animals such as calves, sheep, and goats.

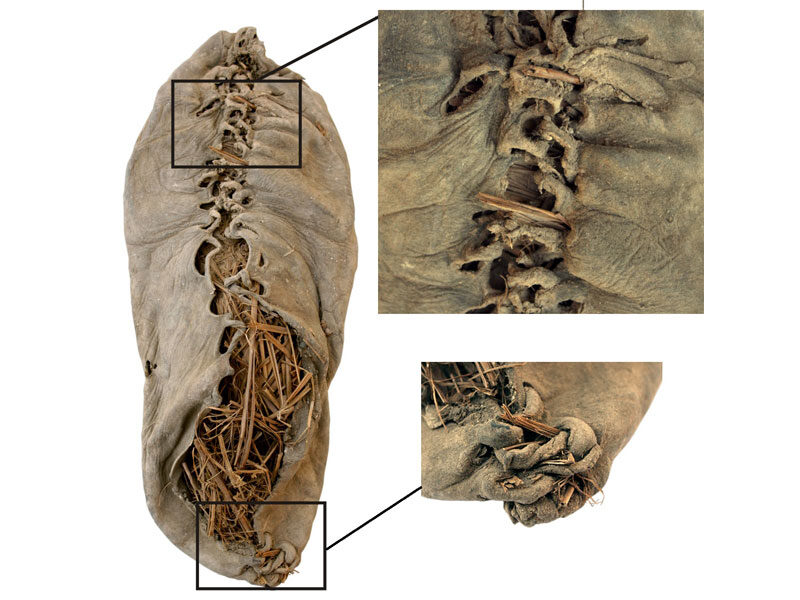

Let's breakdown the structure of a cowhide:

Epidermis: The outermost layer of the raw skin, the barrier between the animal and its environment.

Grain: The uppermost layer of skin, and the most valuable part of the skin to preserve during the tanning process.

Corium: The fibrous structure of the skin below the grain layer. The corium is composed of a weave of collagen fibers making leather exceptionally strong.

The historical structure of cowhide.

Image source: assignmentpoint.com

There are many more layers than you might have thought for a simple hide. Hides can actually be so thick that they are too thick for upholstery use. So, what can you do? That's when splitting comes into play. The top portion of a hide is separated from the bottom portion. Top Grain leather and Full Grain leather are produced from the top grain portion, which is the strongest layer. The bottom layer is referred to as the split leather. This is the layer that is often made into suede.

Suede is not as strong as other leathers but still has its purposes.

Image source: tarrago.com

Hide Configurations

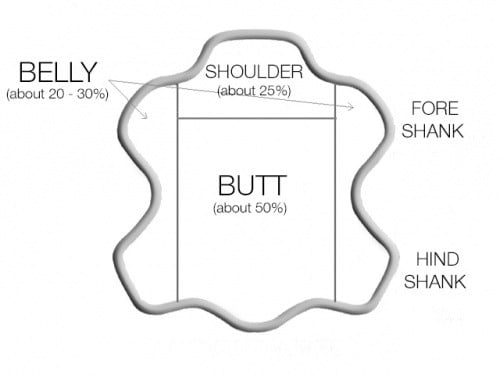

Let's talk about the different types of hides depending on where they are taken from the animal.

Whole Hide: Furniture upholstery leather commonly uses the entire hide, due to the size of patterns.

Side: When a whole hide has been cut in half down the backbone, a side hide has been produced. This configuration is used in smaller leather goods.

Shoulder: Belting leather are sold from shoulder hides. This is cut from the area at the neck region.

Belly: The belly is looser, and used for items such as the rawhide for dog bones or gelatin for capsules.

Butt: The butt is the thickest and strongest part of the hide.

These are parts of the hide to give you a clearer image of where they are cut from.

Image source: leatherdictionary.com

Preparing the Hides

This is an informative video by one of America's oldest leather companies, Moore & Giles. They break down the intricate processes of preparing the hides. These stages of processing are referred to as Beamhouse Operations.

Beamhouse operations consist of:

Soaking: The hide becomes dehydrated from the salt of curing and brining processes. Hides are then soaked in water to reintroduce moisture. Depending on the thickness of the hide, they can be placed in water for a period ranging from 8-20 hours.

Fleshing: Fatty tissue is removed from the black side of the hide. If left intact, this material can prohibit the penetration of chemicals and hinder the preservation process.

Liming: Liming is another word for de-hairing a hide with chemicals. Calcium hydroxide and sodium sulfide are the most common chemicals used in the process. The pH is raised to 11, after many hours, and hides are placed in an alkaline state. This makes the hide swell, making hair removal possible.

Deliming/Bating: this process removes the lime and unwanted chemicals. We don't want unwanted chemicals all over our leather couches. This process can last from a few hours to overnight and lowers the pH to 8 or 9. Ammonium sulphate is a common chemical often used as a deliming agent. Bates are comprised of enzymes.

Pickling: We pickle vegetables, and we also pickle hides. Taking place in the same vessel as bating, pickling places hides in a low pH/ acid state for receiving of tanning chemicals.

What is the Tanning Process for Leather?

When a human tans, it means their skin gets darker from exposure to the sun. When humans tan too much, their skin will almost turn leathery in old age. A similar transformation takes place with leather tanning. It means converting perishable animal hides, into toughened leather.

These are two common viable methods of tanning:

Mineral tanning: uses mineral salts that produce soft, pliable leather. This is a method used for most light leathers and can shorten the tanning period to days or even hours. Mineral agents used are chromium salt, aluminum salts, and zirconium salts.

Vegetable tanning: the oldest of the tanning methods. Extracts are taken from trees and plants and processed into tanning liquors. The hides are then soaked in vats or drums of increasingly strong liquor until they are sufficiently tanned.

Finish Types

When you buy a leather sofa, a leather chair, or any type of furniture that is leather, these are the varieties of looks that you most often find.

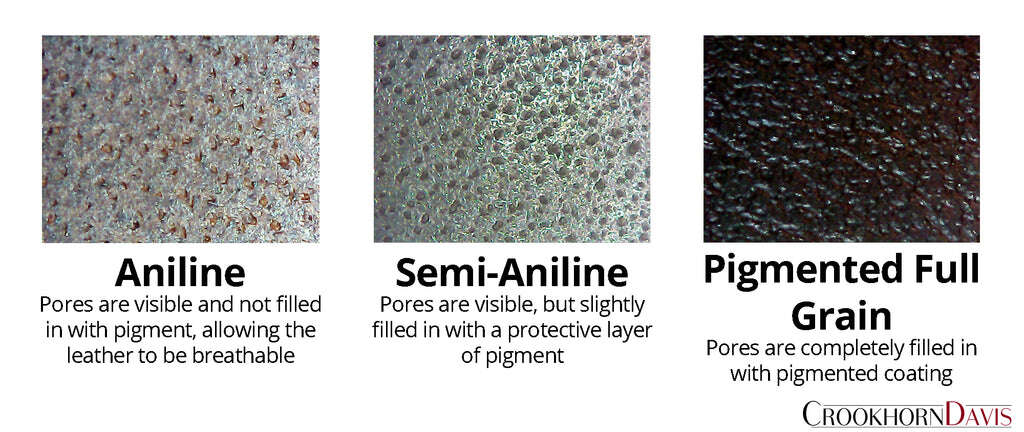

Image source: crookhorndavis.com

Aniline leather is produced by completely immersing hides in a dye bath of transparent aniline dyes. They are the most natural and often the most pristine of hides are used. When you see natural markings on hides, it is most likely an aniline-dyed leather.

Semi-aniline leather is also fully dyed through like aniline leather but has a light surface coating and a small amount of pigment in the base coat. This surface coat helps with leathers' stain resistance.

Pigmented leather is the type of leather that looks less natural in appearance, and has a polymer coating on the surface. This polymer coating acts as a protective coating on the hide's surface. So, the finish may not look the most natural, but your leather is guaranteed to have greater wear resistance, water resistance, and protection from staining.

That's a Lot of Leather Information

We hope you found this leather guide helpful and informative. It's so interesting to see how leather has been a part of our lives for as long as we were able to make tools. Mankind has always had a use for the material, and now we have developed intricate methods for the furniture in our homes.

The Devon Leather Sectional by La-Z-Boy.

The Furniture Mall has plenty of leather furniture to look through. Now you are filled with knowledge on leather furniture and can be an expert while you shop. We have locations in Topeka, Olathe, and Lee's Summit, come pay us a visit when you are finding yourself desiring the natural beauty and durability of a leather sofa.